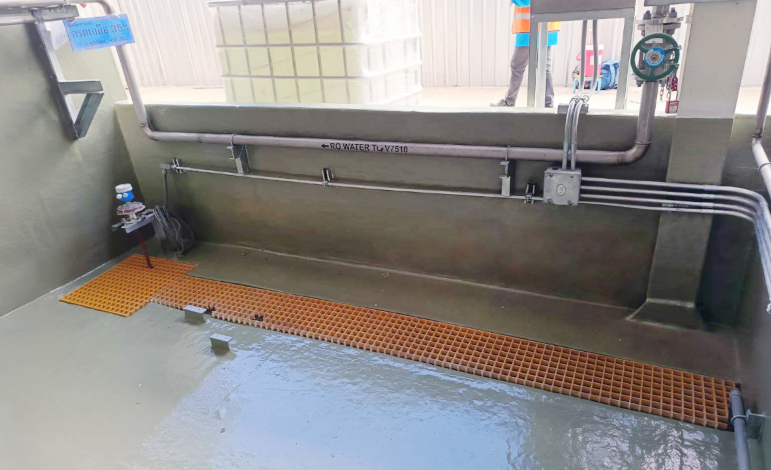

When it comes to FRP Lining, most people recognize it as a superior solution for chemical corrosion protection and extending the lifespan of the surface. Many industries invest in FRP Lining for chemical storage tanks, wastewater treatment ponds, and surfaces that are regularly exposed to corrosive chemicals because it is a cost-effective, long-term investment. A high-quality FRP Lining application can maintain surface durability and operate efficiently for decades.

However, proper and consistent maintenance is vital. This article introduces simple steps for maintaining your FRP Lining surfaces that your facility can perform to extend service life and save on long-term repair costs.

1. Regular Inspection of the FRP Lining Surface

Continuous monitoring is the core of preventive maintenance. FRP Lining surfaces should be visually inspected at least 1–2 times per year, or more frequently depending on actual operating conditions.

- Cracks: Small cracks on the FRP surface are warning signs. Immediate repair is necessary to prevent chemicals from penetrating into the structural fiberglass layers.

- Blistering/Bulging: This indicates that moisture or chemicals may have penetrated beneath the FRP Lining layer. Consult a specialist for an immediate evaluation.

- Delamination: This occurs when the fiberglass layers separate from the substrate or from each other. If you notice peeling or separation, it means the bonding has failed. You should contact an FRP Lining repair expert immediately.

- Discoloration: Significant color changes may indicate a severe chemical reaction. You should verify if the resin specifications used in the FRP Lining process are compatible with the current chemicals.

2. Proper Cleaning Methods

The accumulation of chemical residues or waste can accelerate the degradation of the FRP surface. Regular cleaning helps remove potentially corrosive deposits.

- Rinse with Clean Water: In most cases, using clean water with appropriate pressure is sufficient to wash away dirt and residues.

- Avoid Metal Brushes or Scrapers: When cleaning the FRP Lining, avoid using hard tools or metal brushes that could scratch the surface. Deep scratches can eventually lead to cracking.

3. Prompt Repairs

Minor damage, if neglected, can develop into major problems over time. Immediate repair of cracks or chips in FRP Lining is key to maintaining corrosion resistance.

- Spot Repairs: Small damaged areas should be repaired promptly to prevent further deterioration.

- Consult Specialists: If the damage is extensive or cracks reach the structural layer, call a professional FRP expert team to evaluate and perform technical restoration.

4. Control of Chemicals and Temperature According to Resin Grade

Each FRP Lining is designed to withstand specific chemical types and temperature ranges. Exceeding the resin’s limitations, it will degrade rapidly.

- Monitor Temperature Limits: Ensure operating temperatures (both the chemical and external environment) do not exceed the specified limits for the resin type used (e.g., Isophthalic or Vinyl Ester).

- Chemical Changes: If you change the type or increase the concentration of chemicals, consult an expert to verify if your existing FRP Lining can withstand the new conditions.

5. Periodic Professional Inspections

Beyond internal checks, you should hire a professional FRP Lining company to conduct a detailed audit every 1-2 years. This is the most cost-effective investment for Preventive Maintenance (PM).

- Thickness Testing: To ensure the FRP Lining thickness still meets the required protection specifications.

- Hardness Testing: Using specialized tools to confirm the resin maintains its structural integrity and resistance to wear.

- Leak and Spark Testing: Utilizing specific equipment to detect pinholes or weak points that could lead to leaks.

Maintaining FRP Lining is not a complicated task. By prioritizing these simple inspection and cleaning steps, you can ensure that your facility's FRP Lining remains an effective barrier against corrosion for many years.